Advantages and Disadvantages of Plate Heat Exchanger

This Kind of Customer Service is Above and Beyond. 3 The operating temperature is limited by the temperature resistance of the gasket material.

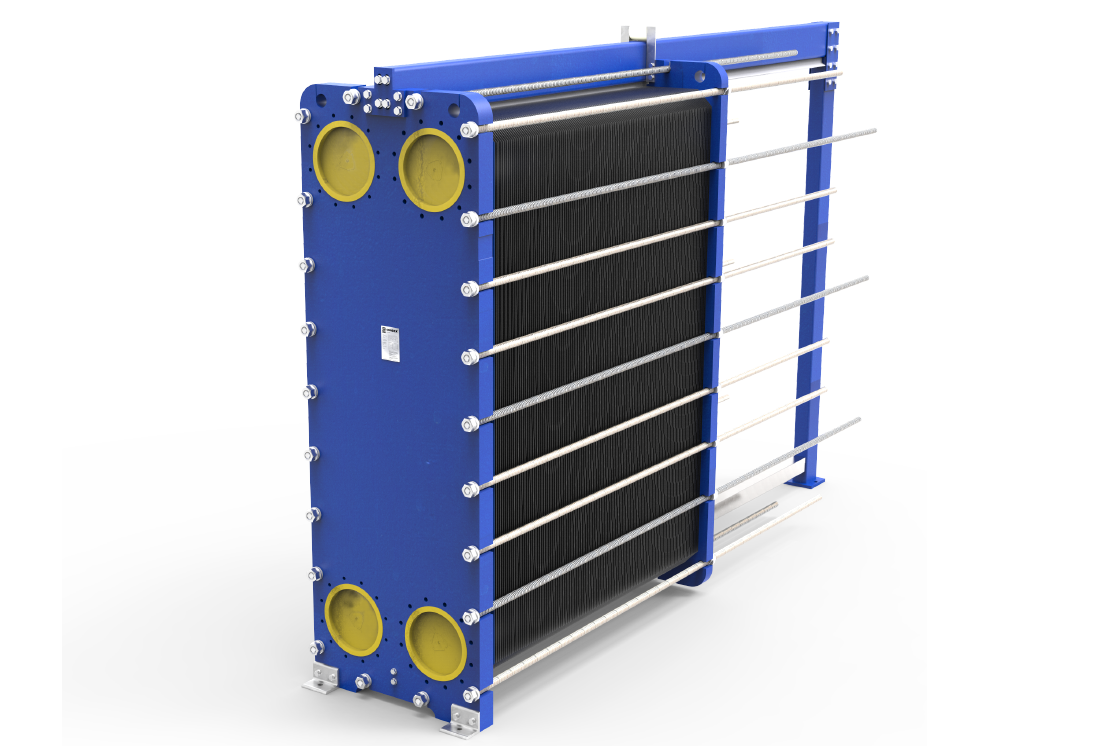

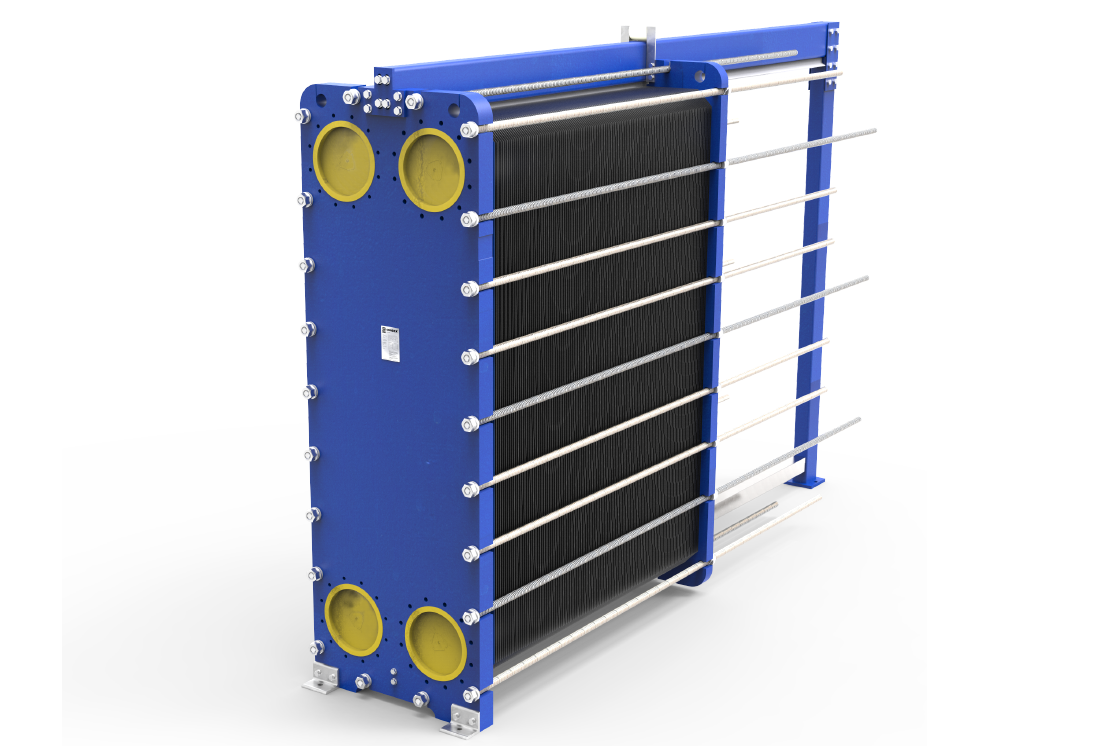

What Is A Plate Heat Exchanger How Does A Plate Exchanger Work

The spiral plate heat exchanger is a high-efficiency heat exchanger device which is suitable for steam-vapor vapor-liquid liquid-liquid and liquid heat transfer.

. Contact Power Systems Specialists Inc. Published May 11 2020. Plate exchangers typically have a larger coefficient of heat transfer as they have more contact area between fluids.

In the condition of same pressure loss the heat transfer coefficient of plate heat exchanger is 3. The counter-flow heat exchanger provides the most thermally effective arrangement for recovery of heat or cold from process streams. It has the characteristics of high heat exchange efficiency small heat loss compact and lightweight structure small floor area and long service life.

Plate Type Heat Exchangers Advantages Simple and Compact in size Heat transfer efficiency is more Can be easily cleaned No extra space is required for dismantling Capacity can be increased by introducing plates in pairs. It also can reach close approaches to the temperatures of their counterparts. It is more troublesome to replace the gasket frequently.

Pdf 2016-10-25 1112 kB. Instruction manual Brazed plate heat exchangers EN. The fluid allows a higher flow rate in the spiral plate and the fluid flows in the spiral direction and the stagnant layer is thin so the heat transfer coefficient is large and the heat transfer.

2Disadvantages of plate heat exchangers 1 Poor sealing and easy to leak. In addition heat exchangers are also used in chemical plants petroleum refineries sewage treatment and nuclear power facilities. Hear What Our Customers Say.

The stainless steel plate heat exchanger covers an area of about 15 to 18 of the shell and tube heat exchanger. It also requires a smaller heat transfer area requiring only ten to twenty percent of the space of a shell or tube. Below are some advantages of using a plate heat exchanger over the ever-popular shell and tube heat exchanger.

If replacement is needed the plates may be removed conveniently as well. The material of the gasket used for different media is different and the temperature and pressure during use are conditions that cannot be ignored and play an important role so how to choose the corresponding media is very important. As long as the number of plates is increased or decreased the purpose of increasing or decreasing the heat exchange area can be achieved.

All the associated costs both capital and operating are worth it for the costs the HX saves. What is the disadvantage of shell and tube. They have a small footprint that requires little to no maintenance space.

It has been widely used in metallurgy mining petroleum chemical industry electric power medicine food. Disadvantage one the problem of tightness. The disadvantages are so few as to be irrelevant.

Advantages of plate heat exchanger. First long gaskets are needed. A counter flow arrangement is thermodynamically.

Advantages and disadvantages of plate heat exchangers. For example the heat transfer surface of the spiral plate heat exchanger with a diameter of 1500mm and a height of 1200mm can reach 130m2. Ad Proudly Serving The Oil Gas FRAC Marine Industrial EPG Markets For Over 30 Years.

The purpose for it is that the way toward completing pressing factor tests isnt pretty much as simple as in the cylinder coolers. Stainless Plate Heat Exchanger Model M15-MFG Alfa Laval Plate And Frame Heat Exchanger Model M15-MFG MAWP 150 email protected 220 deg. Second leakage is probable.

The shell-and-tube heat exchanger has a. Compared with the traditional shell-and-tube heat exchanger which is bulky and occupies a large area the plate heat exchanger is light in weight and occupies a small area. The main disadvantages of plate heat exchangers are classified into three.

Advantages And Disadvantages Of Spiral Plate Heat Exchanger. High heat transfer rate. The plates are removable thus making it easy to clean.

Ad Over 1 Million Products 7000 Trusted Brands Hassle Free Returns. The coolant in radiator coils in an internal combustion engine is one example of a heat exchanger. Both type of heat exchangers have advantages and disadvantages.

Advantages And Disadvantages Of Plate Fin Heat Exchanger. Ad New Used Alfa Laval Plate Heat Exchangers. It is suitable for chemical petroleum solvent pharmaceutical food light industry textile metallurgy steel rolling coking.

Advantages and disadvantages of judicial separation. Plate heat exchanger is a high-efficiency heat exchanger made of a series of corrugated metal sheets. The heat exchanger as a piece of equipment is a simple model and therefore has many applications in industry.

The main advantage is the you can recover heat in your process and this saves money typically a lot of money so they are found in virtually every chemical plant. Ad Find Efficient Solutions for All of Your Heating Needs and Projects at Great Prices. And lastly operation costs as well as investment should also form part of the.

There is basically no welding and the frame can be completely. A huge disadvantage of a PCHE heat exchanger plate is that it is very hard to track down spillage in it. In a counter flow heat exchanger the two fluids flow parallel to each other but in opposite directions.

IOW the benefits outweigh the costs. The most significant advantage of a Plate heat exchanger is that it requires less space than its counterparts. 2 The pressure of use is limited generally not more than 15MPa.

Free Custom Quotes For Your Application. 2 It is easy to change the heat exchange area or flow combination. Only the shell plate of the heat transfer plate of the plate heat exchanger is exposed to the atmosphere so the heat dissipation loss is negligible and no insulation measures are required.

Higher Initial Cost While the rest of the process is of extremely low cost the initial cost is a bit higher.

Advantages And Disadvantages Of A Plate Heat Exchanger Stoll

Advantages And Disadvantages Of Pche Heat Exchanger Plate Stoll

Maintaining A Plate Heat Exchanger 2002 03 01 Process Heating

No comments for "Advantages and Disadvantages of Plate Heat Exchanger"

Post a Comment